Welcome To Akash Pack Tech PVT. LTD.

Pouch Packaging Machine

5000000 INR/Piece

Product Details:

- Material SS

- Feature Highly Efficient, Heavy Duty Machine

- Computerized No

- Automatic Grade Automatic

- Control System Human Machine Interface

- Drive Type Electric

- Color Silver

- Click to View more

X

Pouch Packaging Machine Price And Quantity

- 1 Piece

- 5000000 INR/Piece

Pouch Packaging Machine Product Specifications

- Silver

- SS

- Highly Efficient, Heavy Duty Machine

- Electric

- No

- 1 Year

- Human Machine Interface

- Automatic

Pouch Packaging Machine Trade Information

- 30 Piece Per Month

- 8 Week

Product Description

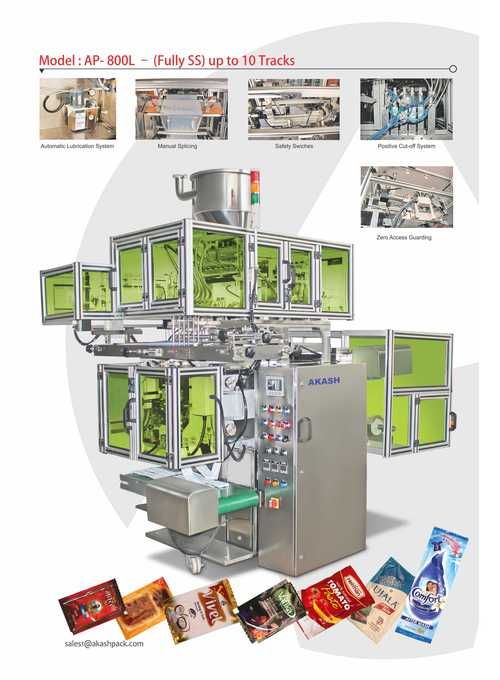

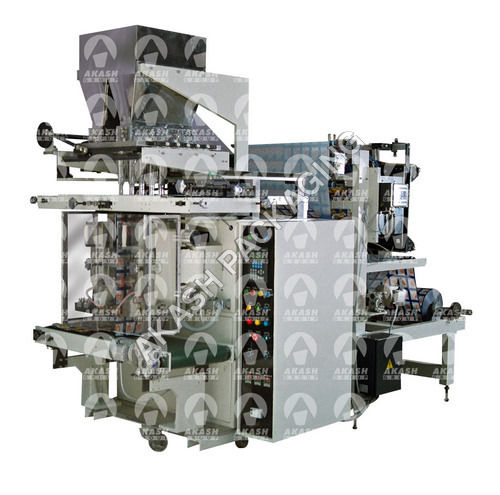

With the leading expertise of professionals, we are involved in the manufacturing andsupplying high quality Pouch Packaging Machine. Premium quality machines are used in the packaging of tea, henna, lubricating oil, detergents and many others. These machines are known for their sturdy construction, longer service life and optimum performance. Our customers can avail these machines at reasonable prices from us. Pouch Packaging Machine is manufactured using excellent quality material in accordance with the international standards.

Salient Features :-

Our premium range of Fully Automatic FFS Machine (Pouch in Pouch) is an ideal solution to pack the pouched products into another pouch. To ensure the safety of users, it is properly enclosed and is provided with 3 side seal/4 side seal/pillow pack. It is AC driven and can go up to the speed of 35 PPM. Further, it is incorporated with weight adjustable disc mechanism up to +/- 5 gms. Pouch packaging machines are extensively used for the pouch filling of free flow powder and granules of products like tea, coffee, henna, etc. These machines are available at competitive prices and are pneumatically driven.These machines are available at competitive prices and are pneumatically driven.

Technical Specifications :-

- Fully automatic PLC controlled pneumatic operated.

- Intermittent motion sealing mechanism.

- Suitable to pack product packed pouch into another pouch (Online process)

- Product : Tea/Coffee/Henna and other free flowing powder/granules.

- Sealing type : 3 side seal/4 side seal/pillow pack.

- Speed : up to 35 PPM

- Speed control : AC drive

- Weight adjustment : Weight adjustable disc +/- 5gms.

- Model : International standard (GMP)

- Safety features : Totally enclosed.

- Electrical/Electronic/Pneumatic components: - CE certified from O.E.M

Exceptional Efficiency and Performance

Built to maximize productivity, this pouch packaging machine enables rapid and consistent packaging operations, reducing downtime and optimizing throughput. Its robust construction ensures long-lasting service even in demanding environments.

Advanced Control System

Featuring a Human Machine Interface, operators benefit from intuitive controls and real-time monitoring. The system simplifies machine adjustments while maintaining high precision throughout every packaging cycle.

FAQs of Pouch Packaging Machine:

Q: How does the pouch packaging machine enhance efficiency during operation?

A: The machine is designed with a highly efficient mechanism and automatic grade features, allowing quick and consistent pouch packaging. The electric drive and HMI control system help streamline processes, resulting in faster turnaround for packaging tasks.Q: What are the main materials used in the construction of this pouch packaging machine?

A: This machine is primarily constructed from stainless steel (SS), providing excellent durability, corrosion resistance, and a professional silver appearance, suitable for industrial environments.Q: When is it recommended to schedule periodic maintenance for this machine?

A: Routine maintenance is recommended every six months to ensure optimal operation. However, its heavy-duty design and robust stainless steel construction minimize frequent servicing needs.Q: Where can this pouch packaging machine be installed and utilized?

A: Ideal for industrial settings, the machine is suitable for use in factories, packaging plants, and large-scale production facilities. As an exported product manufactured in India, it meets international standards for deployment globally.Q: What is the process for operating the machine using the Human Machine Interface control system?

A: Operators use the Human Machine Interface to configure parameters, start packaging cycles, and monitor performance. The interface offers a straightforward approach to controlling the automated functions, ensuring precise and reliable operations without the need for computerized systems.Q: How does the machine benefit exporters, manufacturers, and suppliers in India?

A: With its automatic operation, heavy-duty design, and reliable warranty, the machine increases productivity and reduces manual labor costs. Exporters, manufacturers, and suppliers benefit from its robust performance and minimal maintenance, supporting efficient international trade.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free